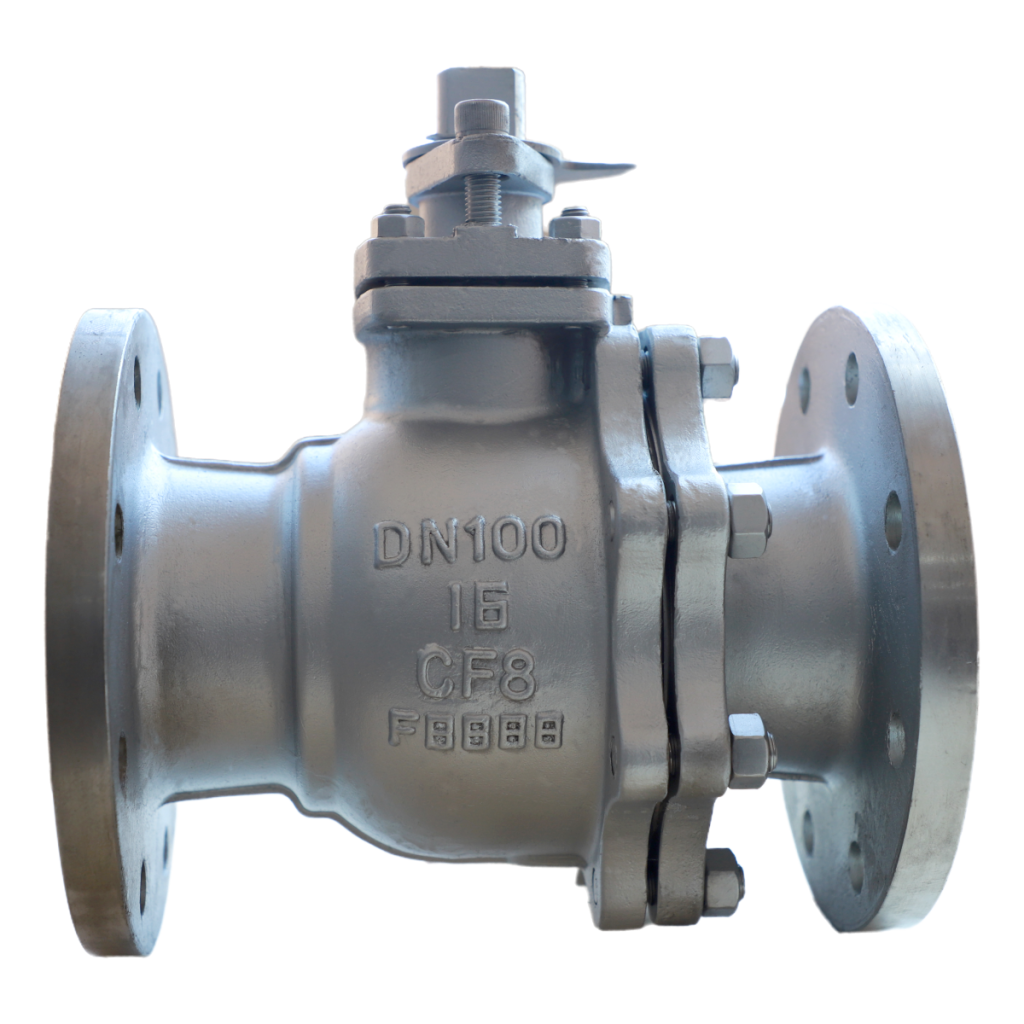

Full port and standard port ball valves differ in how much fluid they let through. A full port ball valve has an opening that matches the pipe size, allowing unrestricted flow. A standard port ball valve has a smaller opening, which slightly reduces flow but costs less.

In this post, we’ll discuss how these valves work, where they fit best, and how to choose the right one for your system.

A full port ball valve allows fluid to move without restriction. Because its bore is the same size as the pipe, pressure loss is minimal.

Benefits:

These are common in industries that require high flow, such as oil and gas, water treatment, and chemical processing.

A standard port ball valve has a smaller bore, meaning it slightly restricts flow. While this creates a small pressure drop, it’s not an issue in most systems.

Benefits:

Standard port ball valves work well in plumbing, HVAC, irrigation, and general water distribution.

A v port ball valve has a V-shaped opening in the ball, allowing for precise control over flow rate. Unlike standard and full port ball valves, which primarily serve as on/off valves, v port ball valves offer better flow regulation.

Benefits

These are best for process control systems requiring steady, adjustable flow rates.

Now that we’ve introduced the different types, let’s compare full port vs standard port ball valves in more detail. The main difference comes down to bore size and flow capacity.

| Feature | Full Port Ball Valve | Standard Port Ball Valve |

| Bore Size | Matches pipe diameter | One size smaller than the pipe |

| Flow Restriction | No restriction | Slight restriction |

| Pressure Drop | Minimal | Higher |

| Best Use Cases | High-flow, high-pressure systems | General plumbing, HVAC, irrigation |

| Cost | Higher due to larger size | More affordable |

| Clogging Risk | Lower due to full opening | Higher due to reduced bore |

Full port ball valves work best when you need maximum flow with no restrictions.

You can use them when pressure drop needs to be minimized, especially in high-pressure systems.

They also handle thick fluids and solids without clogging, making them ideal for industries like oil and gas.

Best for:

Standard port ball valves work best when some flow restriction is acceptable.

You can use them in systems where saving space and reducing costs matter more than full flow.

They are a common choice for applications where a small pressure drop won’t impact performance.

Best for:

Picking the right valve depends on what your system needs.

If flow efficiency and minimal pressure drop matter most, go with a full port ball valve. If space and budget are bigger concerns, a standard port ball valve will get the job done. For more control over flow rates, a v port ball valve is the better choice.Lianke Valve offers high-quality ball valves built for performance. If you’re not sure which one fits your system, reach out—we can help you find the right fit.

Gate valves control fluid flow in various industrial applications. They can completely stop or allow flow, depending on the valve’s position. Valves, in general, share the same function — but what makes gate valves different? This article will explore what gate valves are, how they work, their components, types, and common issues, among other important […]

In Brazil’s booming sugar industry, industrial strainers play a crucial role in ensuring clean, uninterrupted production during juice clarification, sugar syrup filtration, and the crystallization process. With sugar mills handling high-viscosity, abrasive fluids like massecuite and syrup, selecting a reliable strainer manufacturer is essential for maintaining syrup purity, minimizing downtime, and meeting hygiene standards. This […]

South Africa’s gold mining sector relies heavily on robust flow control systems that can withstand abrasive slurry and harsh tailings. Heavy-duty pinch valves play a crucial role here, offering durability, low maintenance, and resistance to extreme pressure. In this guide, we rank the Top 5 Heavy-Duty Pinch Valve Manufacturers South African mines trust for reliability. […]

Desalination facilities in Saudi Arabia face one of the most extreme operating environments—high salinity, abrasive media, and fluctuating brine discharge pressures. In this high-demand sector, pinch valves play a vital role in managing flow control for seawater reverse osmosis (SWRO) and thermal desalination processes. This guide ranks the top 5 pinch valve manufacturers for Saudi […]