Gate valves control fluid flow in various industrial applications. They can completely stop or allow flow, depending on the valve’s position.

Valves, in general, share the same function — but what makes gate valves different?

This article will explore what gate valves are, how they work, their components, types, and common issues, among other important aspects.

So, read on to learn more.

A gate valve is a type of valve that controls the flow of fluids (liquid or gas) by lifting a gate or barrier out of the path of the fluid.

It is often used when a straight-line flow of fluid and minimum flow restriction are required, ensuring an unobstructed flow path.

The gate valve gets its name from the gate mechanism inside, which acts like a door opening and closing to regulate flow.

The primary purpose of a gate valve is to start or stop the flow of fluid completely.

Unlike valves designed for throttling purposes, gate valves are typically used in systems where flow needs to be fully open or fully closed.

Their simple design makes them reliable for high-pressure applications, but they are not recommended for precise flow control.

A gate valve operates by moving a disc (gate) perpendicular to the flow.

When the valve is opened, the gate lifts out of the flow’s path, allowing fluid to pass through.

When closed, the gate seals off the flow.

The gate is connected to a stem, which can either rise or remain stationary, depending on the valve type.

Gate valves require multiple turns to fully open or close, ensuring gradual flow adjustment.

Gate valves are composed of several key components, which are as follows:

| Gate Valve Parts | Description |

| Body | The gate valve body, is the main part of the valve that holds the other components and connects to the pipeline. It supports the gate mechanism, facilitates fluid flow, and ensures a tight seal. |

| Bonnet | This covers the valve’s internal components and provides maintenance access. |

| Gate | The movable disc that blocks or allows flow through the valve. |

| Stem | This connects the gate to the actuator or handwheel and moves the gate up and down. |

| Seat | A part that ensures a tight seal between the gate and the body when the valve is closed. |

When it comes to gate valves, four main types stand out due to their unique characteristics and applications: resilient seated gate valves, wedge shaped gate valves, parallel slide gate valves, and knife gate valves. Each type offers distinct advantages tailored to specific industrial needs, ensuring efficient fluid flow control and reliability.

Resilient seated gate valves feature a wedge encapsulated in resilient material, providing a superior seal, particularly in water distribution systems. These valves excel in offering a tight seal, even around small solids present in the fluid, enhancing performance over traditional metal seated gate valves. Their design ensures reliability and longevity, making them a popular choice for various applications.

have an inclined gate that creates a tight seal with two angled seats, offering better sealing in high-pressure conditions. Metal seated gate valves use a wedge mechanism within the gate valve body, which can trap solids in the fluid, but they provide certain advantages over resilient seated gate valves, particularly in water distribution systems.

Subtypes include solid, flexible, and split wedges.

feature a flat, parallel-faced gate that fits between two parallel seats. These valves offer tighter sealing and smaller closing torques, making them ideal for higher-temperature applications and minimizing dirt accumulation on seating surfaces. They are also known for their safety benefits and operational efficiency.

Both types are used based on specific operational requirements.

A knife gate valve is a specialized type of gate valve designed to handle thick fluids, slurries, and powders. Unlike typical gate valves, the knife gate valve features a sharp-edged gate that can cut through dense materials, making it highly effective in challenging environments.

The knife gate valve operates by using a sharp-edged gate, often made from durable materials like stainless steel or tungsten carbide, to slice through the fluid or slurry. This design ensures that the valve can handle high-viscosity fluids without clogging or sticking. The gate is moved by a handwheel or actuator, which allows it to cut through the material and regulate the flow.

These valves are particularly useful in industries such as mining, chemical processing, and pulp and paper, where the ability to manage thick or abrasive fluids is crucial. Knife gate valves are not typically used for precise flow control but excel in applications where robust performance and reliability are needed to handle challenging materials.

Gate valves are manufactured from various materials to suit different applications:

Gate valve actuation refers to the method by which a gate valve is operated, and it can significantly impact the valve’s performance and suitability for different applications. There are three primary types of gate valve actuation: manual, pneumatic, and electric.

Manual Gate Valve Actuation: This involves using a handwheel or lever to operate the valve. Manual gate valves are often found in applications where the valve does not need to be operated frequently, such as in water treatment plants or certain industrial processes. The simplicity and reliability of manual actuation make it a cost-effective choice for many settings.

Pneumatic Gate Valve Actuation: Pneumatic actuation uses compressed air to move the valve. This type of actuation is ideal for applications requiring quick and frequent operation, such as in chemical processing plants or oil and gas refineries. Pneumatic actuators provide rapid response times and can be automated for enhanced control.

Electric Gate Valve Actuation: Electric actuation employs an electric motor to operate the valve. This method is often used in applications where remote operation or high precision is necessary, such as in power plants or complex industrial processes. Electric actuators offer precise control and can be integrated with advanced control systems for automated operation.

Choosing the right type of gate valve actuation depends on the specific requirements of the application, including the frequency of operation, the need for remote control, and the level of precision required. Each type of actuation offers distinct advantages, making it essential to match the actuation method to the operational needs.

Several common problems can arise with gate valves, including:

Maintaining a gate valve can extend its service life. Here are some tips:

Periodically inspect the valve for signs of wear, corrosion, or debris. Regular inspections help identify potential issues early, allowing for timely intervention and preventing major failures. Pay special attention to the valve body and stem, as these areas are prone to corrosion and wear. Use appropriate tools to check for any misalignment or unusual sounds during operation.

Ensure that moving parts like the stem are well-lubricated to prevent friction and wear. Proper lubrication reduces the risk of mechanical failure and extends the lifespan of the valve. Use high-quality lubricants that are compatible with the valve material and the fluid being controlled. Regularly check the lubrication levels and reapply as needed to maintain optimal performance.

Clear any debris from inside the valve to avoid blockages. Debris buildup can obstruct fluid flow and cause the valve to malfunction. Regular cleaning is essential, especially in environments with high particulate matter. Disassemble the valve if necessary to access and clean internal components thoroughly. Ensure all parts are dry before reassembly to prevent rust and corrosion.

Make sure the valve is installed correctly with appropriate support to avoid pressure on the piping. Improper installation can lead to leaks, misalignment, and increased wear. Follow the manufacturer’s installation guidelines and ensure that the valve is supported adequately to handle the operational pressures. Verify that all connections are secure and that the valve is positioned correctly to allow for smooth operation and maintenance access.

Gate valves are ideal for on-off control, providing minimal flow restriction when fully open.

Ball valves offer versatile operation, suitable for both on-off control and throttling, due to their spherical disc design.

Check valves, on the other hand, are designed to prevent backflow, automatically closing to maintain unidirectional flow.

Understanding the differences among these valves is crucial for selecting the right one based on specific application requirements and operational needs.

| Valve Variety | Difference |

| Gate Valve | Primarily used for on-off control, best for applications where full flow is needed. |

| Ball Valve | Uses a spherical disc to control flow and can be used for both on-off control and throttling. |

| Check Valve | Prevents backflow in systems and automatically closes when the flow reverses. |

Gate valves can be either manual or automatic. Manual gate valves use a handwheel, while automatic versions (like gate valve pneumatic) use actuators powered by compressed air, electricity, or hydraulics. In both manual and automatic gate valves, precise control over the valve position is crucial for effective fluid flow management and preventing issues like flow regulation and erosion.

A gate valve is also referred to as a “sluice valve” due to its function of controlling fluid flow by moving a gate up and down.

In rising stem gate valves, the position of the stem indicates whether the valve is open or closed. If the stem is up, the valve is open. In non-rising stem valves, the handle position typically indicates the valve status.

No, gate valves are not quick-opening. They require multiple turns of the handwheel to fully open or close, which ensures smooth, gradual control of fluid flow.

Yes, gate valves are commonly used in gas applications due to their ability to handle high-pressure conditions and provide a tight seal when closed.

Gate valves should not be used for throttling or flow control, as the partially open position can cause turbulence and damage to the valve components over time.

Gate valves are commonly used in water supply systems, oil and gas pipelines, chemical plants, and other industrial applications where complete isolation of flow is required.

The primary benefit of a gate valve is its ability to provide a tight seal when fully closed, making it ideal for applications requiring complete isolation of flow.

Gate valves are mainly used in systems where full flow or complete shutoff is needed, such as in pipelines for water, oil, and gas.

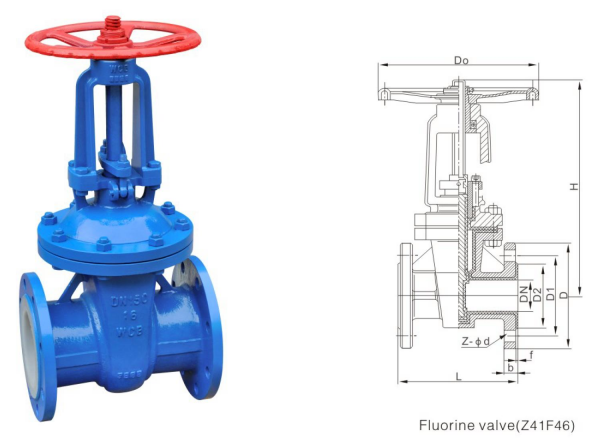

Lianke Valve Co., Ltd., established in 1982, is a reputable manufacturer specializing in high-quality valves, including fluorine-lined gate valves.

With a focus on innovation and customer satisfaction, Lianke offers a wide range of stainless steel gate valves, flanged gate valves, and more.

Our advanced manufacturing processes and rigorous quality control ensure that each valve meets the highest standards — making us a reliable partner for various industries worldwide.

Whether you need a gate valve pneumatic or a stainless gate valve, Lianke has the expertise and inventory to meet your needs.

Contact them today to get started.

Resources:

Gate valves control fluid flow in various industrial applications. They can completely stop or allow flow, depending on the valve’s position. Valves, in general, share the same function — but what makes gate valves different? This article will explore what gate valves are, how they work, their components, types, and common issues, among other important […]

In Brazil’s booming sugar industry, industrial strainers play a crucial role in ensuring clean, uninterrupted production during juice clarification, sugar syrup filtration, and the crystallization process. With sugar mills handling high-viscosity, abrasive fluids like massecuite and syrup, selecting a reliable strainer manufacturer is essential for maintaining syrup purity, minimizing downtime, and meeting hygiene standards. This […]

South Africa’s gold mining sector relies heavily on robust flow control systems that can withstand abrasive slurry and harsh tailings. Heavy-duty pinch valves play a crucial role here, offering durability, low maintenance, and resistance to extreme pressure. In this guide, we rank the Top 5 Heavy-Duty Pinch Valve Manufacturers South African mines trust for reliability. […]

Desalination facilities in Saudi Arabia face one of the most extreme operating environments—high salinity, abrasive media, and fluctuating brine discharge pressures. In this high-demand sector, pinch valves play a vital role in managing flow control for seawater reverse osmosis (SWRO) and thermal desalination processes. This guide ranks the top 5 pinch valve manufacturers for Saudi […]