In industrial systems, check valves are critical for preventing backflow, protecting equipment, and maintaining process efficiency. However, improper installation can lead to premature wear, leaks, or even system failure. For engineers, mechanics, and technicians, understanding the technical nuances of check valve installation is essential. This guide breaks down key considerations, supported by industry standards and data, to ensure your valves perform reliably under demanding conditions.

Check valves are simple devices, but their effectiveness hinges on precise installation. Here’s what you need to prioritize:

Position check valves where they’re easily accessible for inspection and maintenance. For example, isolating a pipeline section during repairs requires valves to be strategically placed—ideally near pumps, elbows, or system branches. According to Rangeline, valves installed too close to bends or fittings risk turbulence, which accelerates wear.

Key Rule:

This minimizes turbulent flow, reducing stress on the valve disc and seat.

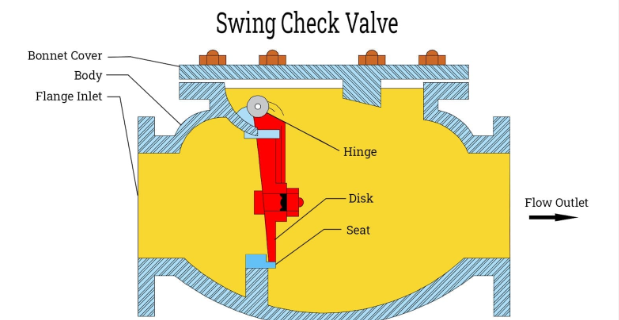

Check valves must align with the system’s flow direction. The valve body typically has an arrow indicating the correct orientation. Gravity-dependent valves (e.g., swing check valves) require vertical installation with flow moving upward. In contrast, silent spring-loaded check valves work in any orientation, including horizontal lines (Milwaukee Valve).

Pro Tip: After installation, verify the valve opens freely in the flow direction. A stuck disc can cause dangerous pressure surges.

The valve’s connection method impacts durability and leak resistance. Below is a comparison of common types:

| Connection Type | Best Applications | Pressure Rating | Ease of Maintenance |

|---|---|---|---|

| Threaded | Low-pressure systems (e.g., water lines) | Up to 150 psi | Simple, but prone to leaks if overtightened |

| Flanged | High-pressure, high-temperature systems | 150–2500 psi | Easy disassembly, requires precise alignment |

| Welded | Permanent, high-integrity systems (e.g., chemical plants) | 2500+ psi | Permanent; no disassembly possible |

Source: Rangeline, Allied Valve

Flanged connections are ideal for systems requiring frequent maintenance, while welded joints suit corrosive or high-pressure environments.

Follow these steps to ensure a secure, leak-free installation:

Valve materials must withstand the fluid’s chemical properties and temperature. For example:

Always cross-reference the valve’s pressure-temperature rating with the system’s operating conditions (Tameson).

Over-tightening threaded connections can strip threads or crack the valve body. For NPT threads, tighten until snug, then add 1/4 to 1/2 turn with a wrench.

Proper check valve installation isn’t just about following steps—it’s about understanding how design, placement, and materials impact long-term performance. By adhering to straight-pipe guidelines, choosing the right connection type, and verifying flow direction, you’ll minimize downtime and maintenance costs.

Gate valves control fluid flow in various industrial applications. They can completely stop or allow flow, depending on the valve’s position. Valves, in general, share the same function — but what makes gate valves different? This article will explore what gate valves are, how they work, their components, types, and common issues, among other important […]

In Brazil’s booming sugar industry, industrial strainers play a crucial role in ensuring clean, uninterrupted production during juice clarification, sugar syrup filtration, and the crystallization process. With sugar mills handling high-viscosity, abrasive fluids like massecuite and syrup, selecting a reliable strainer manufacturer is essential for maintaining syrup purity, minimizing downtime, and meeting hygiene standards. This […]

South Africa’s gold mining sector relies heavily on robust flow control systems that can withstand abrasive slurry and harsh tailings. Heavy-duty pinch valves play a crucial role here, offering durability, low maintenance, and resistance to extreme pressure. In this guide, we rank the Top 5 Heavy-Duty Pinch Valve Manufacturers South African mines trust for reliability. […]

Desalination facilities in Saudi Arabia face one of the most extreme operating environments—high salinity, abrasive media, and fluctuating brine discharge pressures. In this high-demand sector, pinch valves play a vital role in managing flow control for seawater reverse osmosis (SWRO) and thermal desalination processes. This guide ranks the top 5 pinch valve manufacturers for Saudi […]