Self-cleaning filters work differently depending on their type: mechanically cleaned or tubular backwash. Mechanically cleaned filters use internal wiping discs that sweep debris away while your system continues running. Tubular backwash filters reverse the water flow to flush away trapped particles when pressure builds up.

Both auto clean filter systems protect your equipment and improve efficiency by cleaning themselves routinely based on parameters you set.

Self-cleaning filtration systems use pressure differentials as triggers for cleaning cycles.

When debris collects on the screen, pressure increases between inlet and outlet points.

Once this differential reaches the preset threshold (typically 7psi), the system activates its filtration cleaning mechanism.

The filter continues processing fluid during this entire cleaning cycle—maintaining productivity without interruption.

Self cleaning water filter technology offers several advantages over traditional manual filters:

Continuous filtration with automatic cleaning — ideal for high-efficiency industrial systems.

View Product

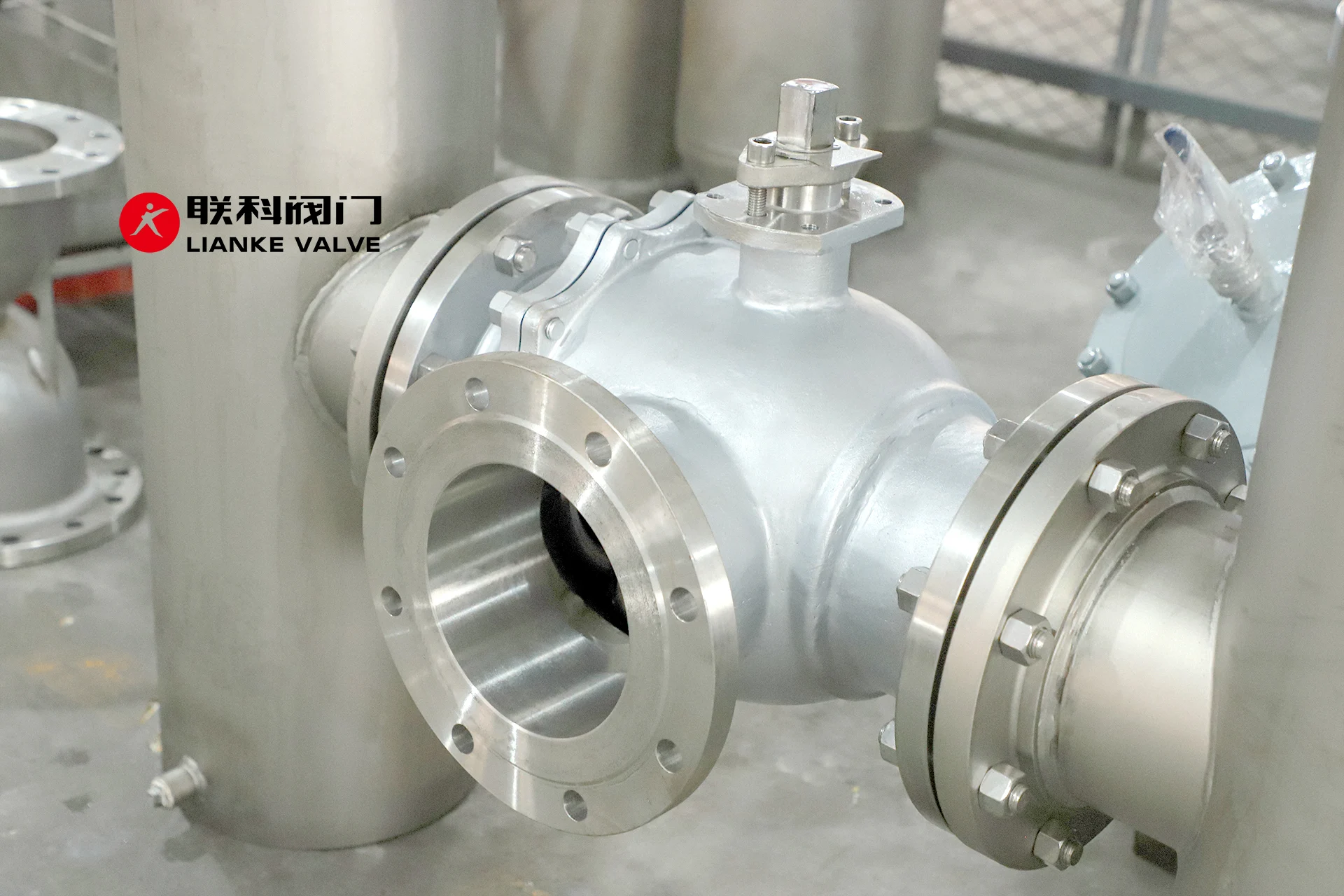

Mechanically cleaned filters are straightforward but ingenious solutions for self cleaning filtration. They use a stainless steel housing that contains a cylindrical screen where all the filtering happens.

When water flows into the filter, it passes through this screen with solid particles getting trapped on the inside surface. The clean water continues flowing out while the contaminants stay behind, gradually building up on the screen.

What makes these filters special is how they clean themselves without stopping your system. When the filter needs cleaning—either based on time, pressure differences, or when you manually activate it—a clever mechanism kicks in.

The cleaning happens through a simple but effective process:

“Your water keeps flowing the entire time, meaning no interruptions to your operations while this filter automatic system maintains itself.

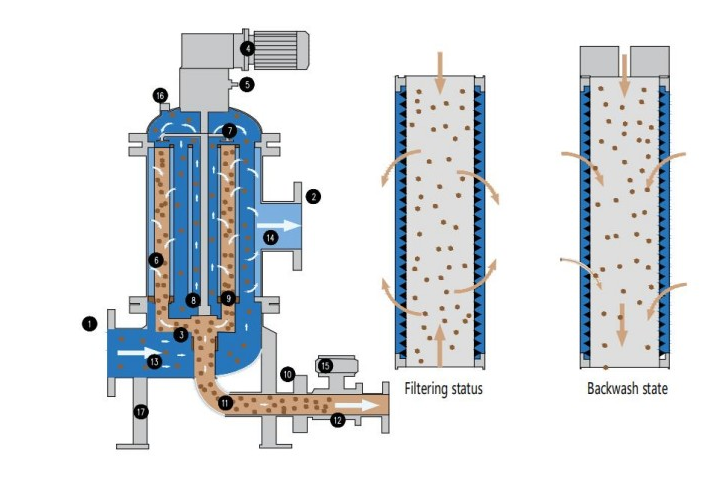

Tubular backwash filters take a completely different approach to keep themselves clean. These systems are particularly good at handling high water flow with smaller granular particles.

Unlike mechanical filters, tubular systems direct water from the outside of the filter element inward. This means all the debris collects on the outside of the filter rather than the inside.

As particles build up on the exterior surface, the system monitors the pressure difference across the filter. When that difference reaches a certain point, it knows it’s time to clean itself.

The cleaning process is elegant in its simplicity:

These self cleaning water filter systems come in two main types: external models that use fresh water for cleaning, and internal versions that use the existing process fluid to flush away contaminants.

While both systems effectively clean themselves, they work in fundamentally different ways.

| Feature | Mechanically Cleaned Filters | Tubular Backwash Filters |

| Particle Collection | Interior filter surface | Exterior filter surface |

| Flow Direction | Inside to outside | Outside to inside |

| Cleaning Mechanism | Physical wiping disc | Reverse flow pressure |

| Best For | Varied contaminant types | Granular particles |

| Flow Rate Handling | Moderate flow rates | High flow rates |

| Maintenance Needs | Very low | Very low |

| Installation Footprint | Larger | More compact |

Both deliver excellent filtration cleaning performance, but each excels in specific applications.

When selecting between self cleaning filtration options, consider these important factors:

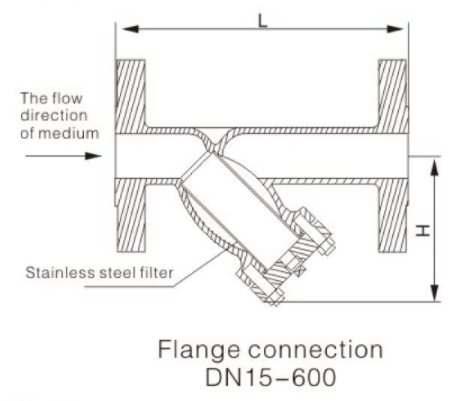

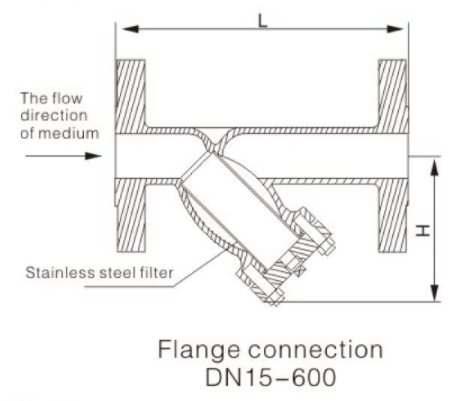

If you’re looking for quality filtration products, our collection of strainers includes options for various applications, from Y-strainers to basket designs. Whether you need to filter out large debris or capture fine particulates, we have filtration solutions engineered for optimal performance in your specific industrial environment.

Self-cleaning filters represent a significant upgrade for any industrial water system. Whether you choose mechanically cleaned or tubular backwash technology, these auto clean filter systems deliver consistent performance with minimal maintenance requirements.

As filtration cleaning technology continues to advance, these systems become even more efficient and adaptable. Consider upgrading to a self cleaning water filter system today to experience the difference in your operations—cleaner water, consistent pressure, and significantly less maintenance headaches.

To install a Y strainer vertically, position it with the pocket pointing down in a downflow line and make sure there’s enough room for maintenance. When done right, vertical Y strainers filter effectively while gravity helps collect debris. Here’s how to do it properly. Why Consider Vertical Installation Many people install Y strainers horizontally, but […]

When choosing an industrial filter system, consider factors such as contaminant characteristics, operating conditions, chemical compatibility, housing configuration, and maintenance requirements. These determine whether your filtration system will protect your equipment effectively or create expensive problems down the line. Below, we take a closer look at each factor and how they impact your purchase decision. […]

Pre-filtration is important because it prevents costly system damage and extends equipment life. When you install the right pre filter, it means that your customer’s entire system stays protected from harmful contaminants. Although many contractors might see it as an optional component, a good pre filter can actually save thousands in repairs and maintenance down […]

Proper strainer placement is critical because it directly affects your pump’s performance. The right placement enables the pump to capture debris before it can damage impellers or clog internal components. You can say it’s difference between a pump that runs trouble-free for years and one that requires frequent repairs and early replacement. How Strainers Protect […]