When choosing a filter or strainer for your system, micron ratings tell you how small the particles are that your filter can catch. In simple terms, the smaller the micron rating, the finer the filter. Whether you’re in water treatment, chemical processing, or any industry that relies on micron filtration, knowing the right micron size can help prevent clogging, protect equipment, and ensure better fluid quality.

This guide will explain micron ratings, compare common sizes, and help you choose the best micron filter for your needs.

Micron ratings indicate the size of particles a filter can trap. One micron equals one millionth of a meter or 0.000039 inches.

The right micron rating ensures that your system filters out unwanted particles without clogging too quickly. A too-small rating may cause fast debris buildup, while a too-large rating may allow contaminants through.

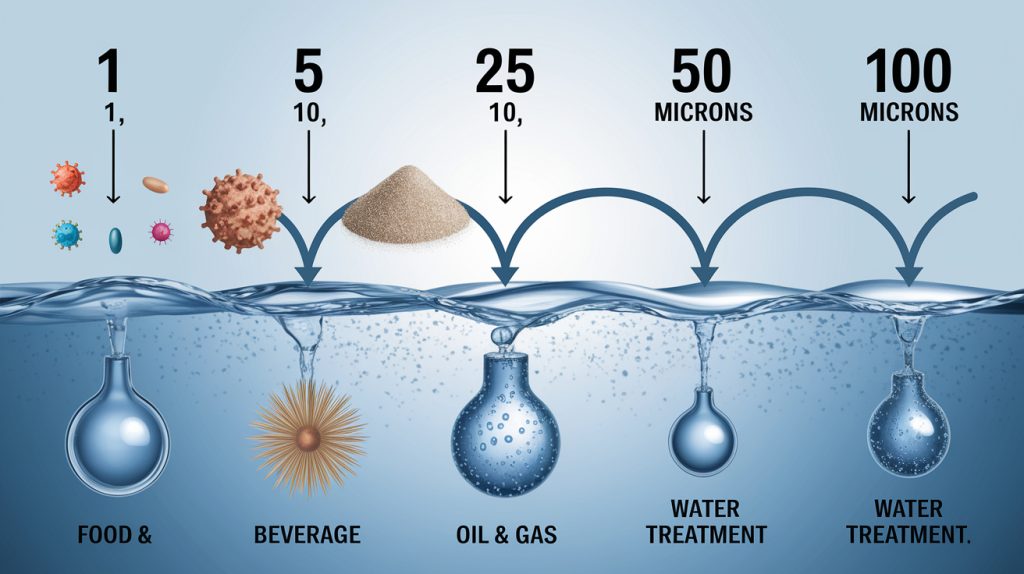

Micron filtering is essential across industries:

Each filter rating serves a purpose. Here’s a breakdown of the most used micron filtration levels.

Removes particles as small as 0.005 mm, including fine dust, silt, and large bacteria. It offers good clarity while allowing a reasonable flow rate.

✅ Best for: Food processing, residential water systems, and polishing filters in multi-stage setups

⚠️ Can clog quickly in sediment-heavy applications; may require pre-filtering.

Removes particles down to 0.01 mm such as fine sand, debris, and pollen. It’s commonly used where moderate filtration is needed without sacrificing too much flow.

✅ Best for: Industrial filtration in oil, gas, and chemical plants

⚠️ May not be effective for microbial contaminants; consider pairing with finer filters.

Filters out particles about 0.025 mm in size, including visible rust flakes and some fine sediment. It strikes a good balance between flow rate and filtration depth.

✅ Best for: Pre-filtration in commercial and industrial water systems

⚠️ Not suitable for applications needing fine particulate control.

Captures large particles around 0.05 mm like sand, scale, and pipe corrosion. Helps protect downstream filters from premature clogging.

✅ Best for: Initial filtration stage in irrigation, HVAC, and industrial processes

⚠️ Will not remove smaller particles or improve water clarity significantly.

This chart shows different micron sizes, what you can see with the eye, and examples of what each size filters. It helps you pick the right micron filter for better micron filtration.

| Micron Size | Visibility | Common Examples |

| 1 micron | Not visible | Bacteria, carbon dust |

| 5 micron | Not visible | Large bacteria, fine sand |

| 10 micron | Not visible | Pollen, cement dust |

| 25 micron | Not visible | White blood cells, textile fibers |

| 50 micron | Visible | Human hair, fine grain particles |

| 100+ micron | Visible | Sand, rust flakes, large debris |

There are two types of micron filter ratings:

Captures 100% of particles at the stated size.

✅ Used in critical filtration like pharmaceutical or microelectronics.

Captures 80–90% of particles at the stated size.

✅ Common in general industrial and residential use.

Selecting the proper micron filtering level depends on:

If unsure, start larger and move smaller in stages to avoid early clogging.

Understanding micron ratings helps you choose the right filter for your specific process. It prevents system damage, reduces maintenance, and improves product or water quality. Whether in a heavy industrial setup or managing residential water, micron filtration ensures efficiency and protection.

If you’re looking for high-quality filtration solutions, Lianke Valve offers durable and reliable filters and strainers built for performance.

🔗 Explore our industrial strainers

When choosing a filter or strainer for your system, micron ratings tell you how small the particles are that your filter can catch. In simple terms, the smaller the micron rating, the finer the filter. Whether you’re in water treatment, chemical processing, or any industry that relies on micron filtration, knowing the right micron size […]

Municipal water doesn’t just show up clean at the tap—it’s the result of a carefully managed process. The liquid filtration process for municipal water treatment plants is the backbone of safe, clean drinking water. From removing dirt and debris to eliminating harmful pathogens, each step in this system ensures water meets strict safety standards. In […]

Choosing the right basket strainer for your system comes down to understanding filtration size, strainer mesh, and how these elements fit into your specific piping setup. Whether you’re working in chemical processing, food production, water treatment, or HVAC, the right strainer ensures system protection, flow efficiency, and long-term equipment performance. This article will help you […]

Installing, operating, and maintaining a basket strainer properly ensures optimal system performance, protects downstream equipment, and extends the life of your filtration system. Whether used in chemical processing, HVAC, food production, or water treatment systems, basket strainers are essential components for removing solid particles from fluids. In this article, we’ll break down the complete lifecycle […]